Today Pharma is one of the Industries Ecor International Advanced Mechanics activities focus on. For this market, the company proposes high-tech solutions producing critical components and complex systems addressed to automatic machines.

Ecor International has entered the sector thanks to the transfer of its long-standing expertise in the Food Industry. In fact, also in the Food Industry it is necessary to guarantee aseptic components maintaining high quality standards and optimizing performances.

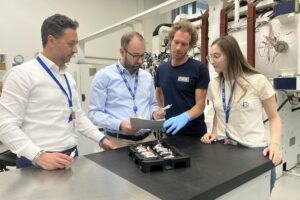

How can we achieve these objectives? We have answered this question with Fabio Pozzebon, Advanced Mechanics Business Manager.

Fabio, today pharma is an ever-changing sector characterized by several capacities for innovation. Which are the main requests from machinery manufacturers?

According to customers’ feedback, today companies are mainly interested in keeping industrial costs down in order to consolidate both their presence in the market and their competitiveness. We can meet these needs in different ways, but summarizing we have to intervene optimizing plants layout, reducing dimensions and streamlining process flows.

How does Ecor International act to meet these needs?

First, focusing on the design phase. Our Engineering Department composed of 30 mechanical and mechatronic engineers and designers deals with the optimization of internal spaces and components design in order to reduce dimensions and eliminate possible contamination risks. More and more frequently, customers ask for customized design solutions: for this reason, we work closely with them adapting the module to the plant. According to needs, we are in any case able to standardize components.

Are there other abilities characterizing the company?

From the organizational viewpoint, another hallmark is the internal management of all manufacturing phases. This way we are able to meet specific needs, from production to final quality controls and the management of technical documentation and plants validation. This provides a real benefit for the customer that can interact with only one supplier for satisfying any requirement saving time and costs.

Which are available technologies addressed to pharma activities in Ecor International production sites?

We are equipped with plants and resources able to perform manual, orbital, automated and robotic TIG welding, in addition to chemical, surface and heat treatments (pickling, passivation and electro-polishing) to increase components performance. For products conformity assessment, we are equipped with cut-edge plants for dimensional and visual controls (also through video endoscope) and non-destructive fluorescent liquid penetrant testing and radiographic testing (on film and digital).

Activities for the Pharmaceutical Industry

For Pharma, the company provides a complete service characterized by the design and production of critical components and complex systems as:

- Critical piping for process fluids;

- Pressurised vessels

- Washing and sterilisation systems

- Complex welded units

- Assembled complex units

These components are addressed to processing and packaging systems for the production of medicaments and vials.

The company produces also complete Skip and CIP/SIP modules and other Taylor-made machines focusing on customers’ specific needs and market demand. All products comply with the International standard ASME BPE.

TO KNOW

- A Skid is a modular and independent plant aimed at interfacing the operation of different and more complex industrial plants, for example the filling line with the plant supplying the product. Skids are modules assembled and tested before the arrival in the production site, allowing this way a rapid integration with the main plant. Every skid is assembled on a platform designed for an easy and safe transport. The layout facilitates the access of technicians in order to optimize production cycle interruptions. For these reasons, every platform has to be specifically designed and built for every Skid system.

- A CIP module (Cleaning-In-Place) is a washing method for internal tubes surface, containers, process equipment, filters and associated plants. The module, using specific machinery, does not require the dismantling of above-mentioned products. On the other side, the SIP method (Sterilization-In-Place) aims at sterilizing the product

- ASME BPE (American Society of Mechanical Engineers: Bioprocessing Equipment) is an international standard developed to support the design and construction of plants and components for the production of biopharmaceuticals. It combines the best practices that guarantee products purity and safety. Companies that strictly comply with this standard can achieve production efficiency, reduce development and production costs and increase safety and quality.

@EcorIntern

@EcorIntern