Ecor Research acquired a new digital radiography system for testing low-thickness welds. The company is one of the first with two x-rays units, equipped with films since 2014 and digital since 2017, ensuring the same quality on the products. This is a strategic system for implementing high quality and fast non-destructive tests on critical components for the aerospace, food, pharmaceutical and advanced mechanics sectors.

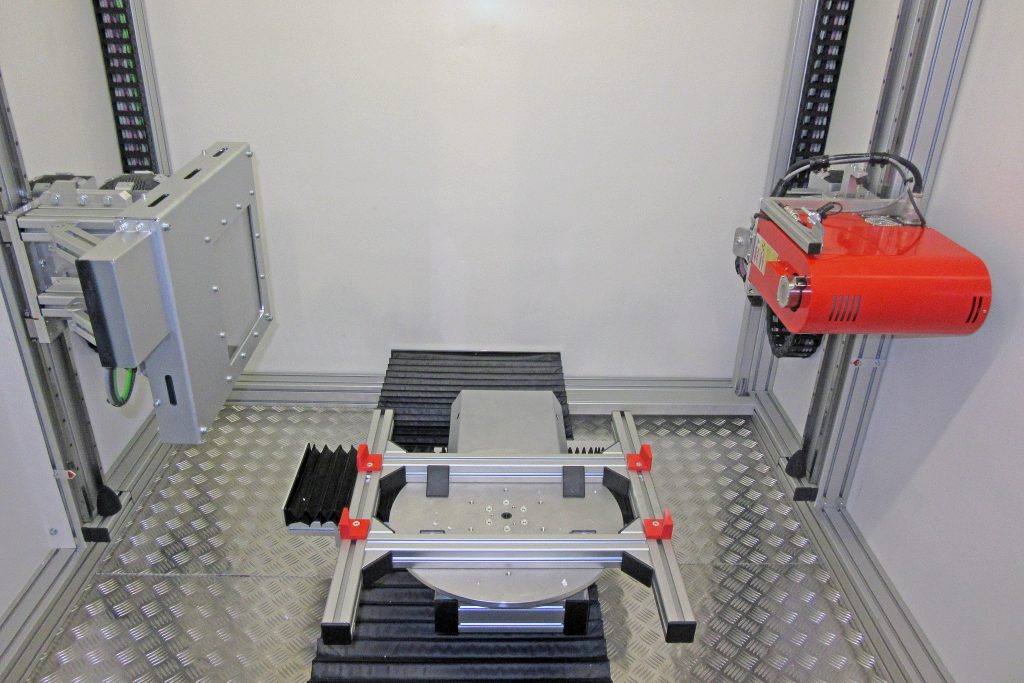

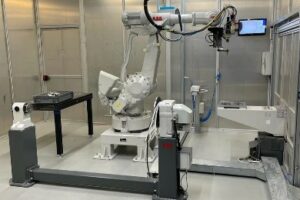

Digital radiography systems use digital x-ray sensors different from traditional analogic films, for acquiring the image of the analyzed component becoming visible on a video display. In particular, the new system in the production site of Ecor Research uses Direct Radiography with digital panels (DDA – Digital Detector Arrays), allowing modifications, image enhancement, filing and electronic transmission after recording the radiographic image.

The radiographic unit can provide an image quality at least equivalent to the one obtained with the highest-class of films, through a 3-10x zoom with 5÷50 µm micro-focus, x-ray tube, 200×200 mm electronic sensor and 200 µm pixel. Since that the film development phase is not necessary, images can be obtained faster even though the quantity is higher: for small dimension components, for instance, 100 digital images can be analyzed in about ten minutes while 20 images in some hours with the traditional methodology.

Another concrete benefit is related to the CNC control in a x-ray shielding cabin, which allows to plan automatic exposition cycles on components having the same shape and position, placing the part only once. Moreover, it is possible to regulate the contrast, brightness and apply the most sophisticated techniques for elaborating the images to analyze different thicknesses on a single image, to measure defects and much more. Eventually, the image filing is done on an electronic device, even if many customers currently require films, when it is necessary to obtain functional shaped geometries to be adapted to difficult access areas.

@EcorIntern

@EcorIntern