From its foundation, Ecor International has chosen to differentiate itself by specializing in primary welding technologies, with a particular focus on laser welding.

The pursuit of excellence in welding has guided every strategic decision, ensuring the maintenance of advanced expertise, specialized skills, and cutting-edge machinery. This commitment has led to continuous updates on the latest technologies and methodologies in laser welding, guaranteeing superior quality results and increased operational efficiency.

The metalworking company considers the skills and abilities of its welders and welding operators to be its most valuable asset. Today, it boasts experienced and talented welders and operators, some with extensive welding experience and others holding international qualifications.

In line with enhancing its employees’ skills, Ecor International is committed to scouting new talent in the welding field. The Italian manufacturing industry is constantly seeking qualified human resources; ‘the talent shortage has become one of the most pressing challenges in the sector in recent times. […] In February 2024, 127,270 skilled workers were in demand, but a staggering 60% of these could not be found.’ (source: MECSPE Observatory 2023)

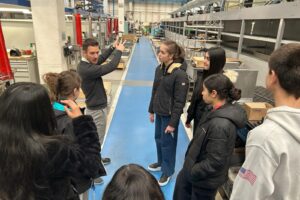

Recognizing the challenges of today’s labor market, the Vicenza-based company has taken a proactive approach by reaching out to the local community and creating internal training opportunities through the Welding Academy.

Technology has always been the second major investment asset for Ecor International.

The company has equipped itself with cutting-edge equipment, including an orbital laser cell, two Sisma systems for low-power pulsed laser welding that enable precise and thin gauge joints, two Trumpf laser systems for deep welding, and a robotic plant capable of welding large volumes and complex geometries.

For precision welding and handling very thin materials, the company employs two Sisma systems equipped with low-power pulsed lasers. These are used for manufacturing critical components with small dimensions. Originally developed for the jewelry industry, these laser welding systems allow the operator to work inside the laser welding booth, ensuring extreme precision, even on materials as thin as a few tenths of a millimeter. They can also handle filler material when needed for joining dissimilar materials.

At Ecor International, low-power pulsed laser welding is employed to weld components for the aerospace sector, such as capillary tubes with a diameter of less than 2 mm used for transporting propulsion fluids (e.g., Xenon).

Another application involves the food packaging sector. Ecor International manufactures cutting devices for automatic packaging machines, using cobalt alloy blades welded to martensitic steel bodies. Thanks to laser welding, even with filler materials, highly critical joints can be achieved for this type of configuration. Ecor International’s engineers have managed to create a product for cutting devices in automatic food packaging machines. This product features high-quality material in the blade, while the rest of the object uses more economical and durable materials, resulting in both economic and technological benefits.

Moreover, anthropomorphic robots handle the welding in ABB’s automated plant, equipped with an IPG source, for complex and spatially expansive welds.

Both the IPG source and the welding head feature laser beam wobble technology, an optical system that enables the laser beam to oscillate rapidly around the theoretical focal point, creating customizable geometric profiles.

This technology allows for the processing of much larger areas with the laser beam compared to conventional laser welding, accommodating components with looser tolerances and fits while improving the appearance of the weld bead surface. For instance, in the heat exchanger sector, this unique laser technology enables the welding of large areas in a short time, ensuring the integrity of the heat exchanger.

Thanks to these facilities and the expertise of the technical staff, Ecor International can address customer requests by assisting them in identifying the most suitable process. The primary focus is on quality, given that these items are typically critical. However, time and cost requirements are not overlooked; they are essential to maintaining competitiveness in the market.

@EcorIntern

@EcorIntern