Welding is one of Ecor International core competences, by means of which the company has developed, in more than forty years of activity, a specialized know how for the production of high benefit components.

Plants in our production sites and professional technicians carry out different welding techniques, using the most advanced technologies available in the market, in order to guarantee the production of complex components from both a geometrical and a quantitative point of view.

Ecor International competences give rise to a high precision process that guarantees small tolerances. Moreover, the company differs for its production flexibility: the productive structure has been organized to perform not only series production but also customized orders in small quantities.

Lastly, product validation forms an integral part of Ecor activities, thanks to the plants for non-destructive testing through penetrating liquids and for x-rays and digital radiography.

Which are the welding techniques used by the company for the production of critical components?

TIG Welding

Highly skilled technicians work in the 35 workspaces for manual TIG welding. The TIG (Tungsten Inert Gas) is an arc procedure with tungsten infusible electrode (hence the name) and inert gas protection, which can be carried out with or without filler metal. It is one of the most developed welding techniques, being able to guarantee high quality junctions and giving the possibility to weld different materials: steel, special steels, Inconel and titanium.

Other four plants perform the automated orbital TIG welding, in which the welding torch mechanically rotates 360 degrees or more around a static piece, generally a pipe, in a continuous process. It is carried out without filler material and it gives advantages in terms of rapidity, repetitiveness and result.

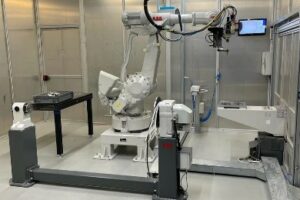

In the three plants for robotic TIG welding, the process is completely automatic. This welding technique guarantees both the continuity and the regularity of the process, in particular for the components that require a long lasting welding. Moreover, it is the best welding technique to use for series production.

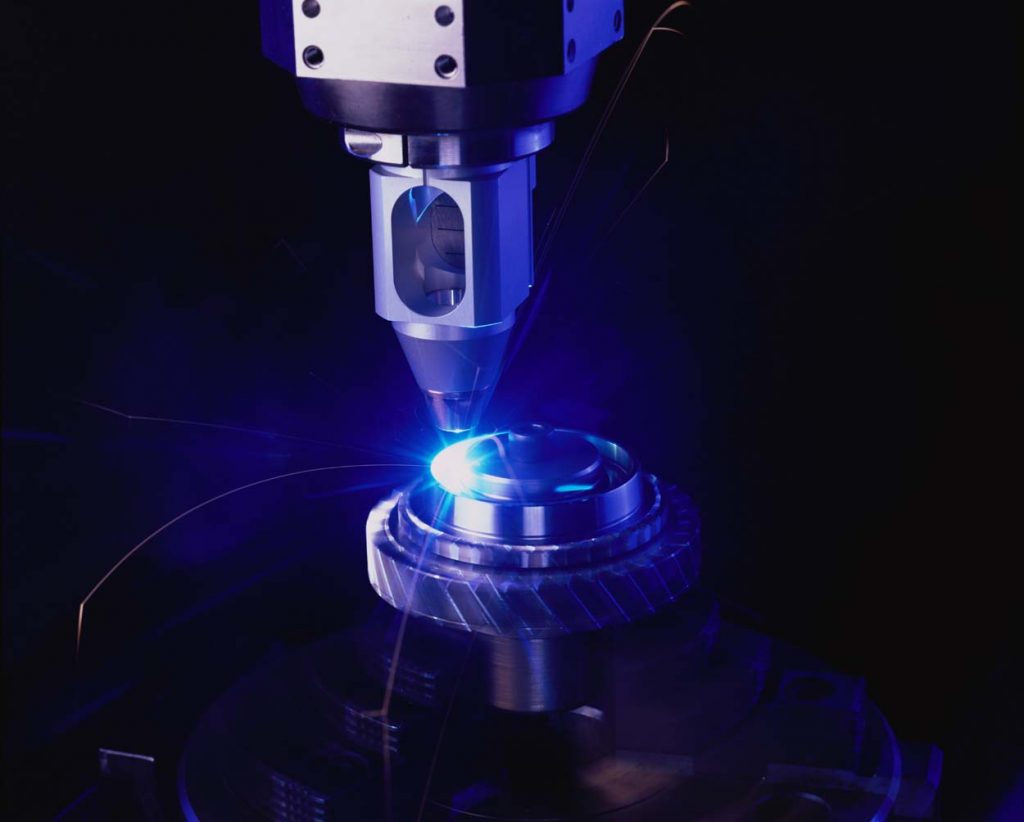

Laser welding

Laser welding is carried out thanks to a high power laser beam that provides a concentrated heat source. In Ecor productive site, there are three plants for the automatic laser welding and one plant for the semi-automatic one. In this case, the aesthetic effect is better and the surface is more uniform, as the weld bead is thinner and cleaner. Laser welding can be carried out with or without filler material.

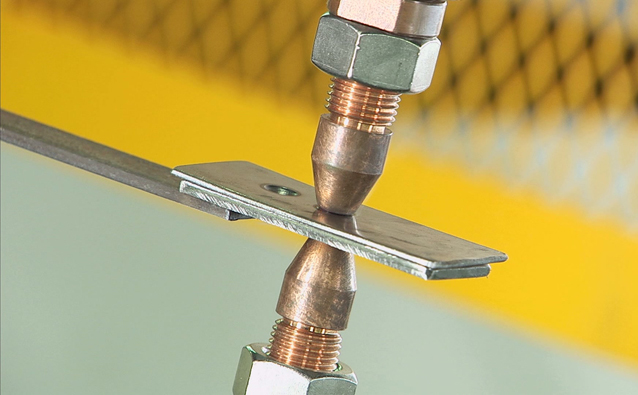

Resistance welding

A plant is dedicated to resistance welding, an autogenous pressure technique in which the material is exposed to electrical resistance heating. In other words, two electrodes touch the material and the electric current heats it up melting the junction area. This method is specifically used when we have to join two overlapping metal sheets.

MIG/MAG Welding

Lastly, MIG (Metal-arc Inert Gas) or MAG (Metal-arc Active Gas) welding is a continuous wire welding technique in which the protection of the soldering bath is assured by a shielding gas, that flows from the torch to the piece that we are welding. The only difference between the two techniques is the type of gas used for the protection of the soldering bath: active or inert. In Ecor International there are two available plants for these processes.

@EcorIntern

@EcorIntern