Sommario

From the very beginning, Ecor International has put the customer at the centre of its efforts, optimising costs, providing timely and accurate information and quality products and services.

Thanks to this combination, Ecor has been able to forge lasting partnerships and establish its reputation as a reliable partner on the market.

Successful combination

One of Ecor International’s secrets is its management capacity, oriented towards innovative methodologies to meet customers’ demands while respecting the environment, safety and health, fundamental factors for the sustainable development of the company and its profitability.

The integration of innovation and industrial production is pursued through the development of competencies thanks to which the company can innovate and realise critical products and highly reliable industrial solutions.

Development cannot be considered as such if, after analysing the context in which it operates to catch the opportunities, the risks are not evaluated with reference to occupational health and safety aspects and the environmental impacts linked to the production cycle.

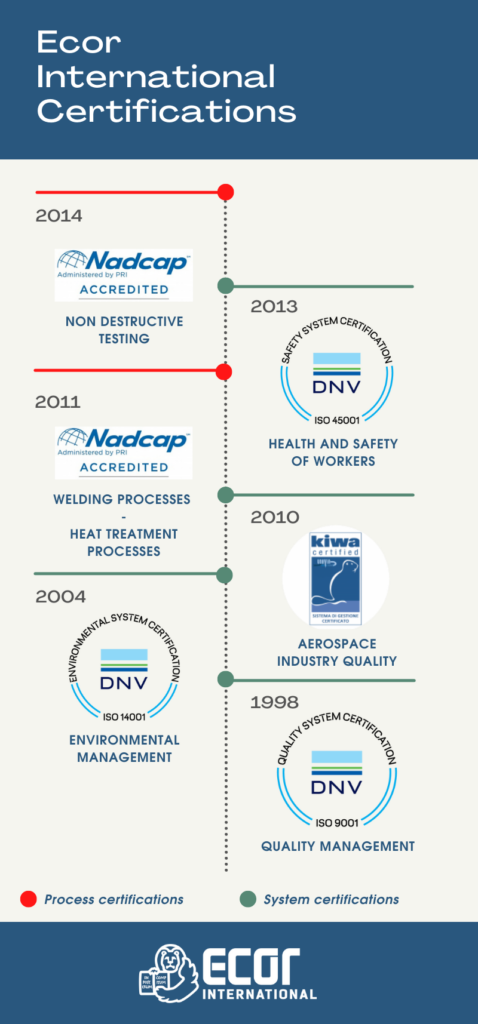

This is why, since the end of the last century, the company has followed a path that has led it to obtain and maintain the most important certifications in the management and organisational sphere, which confirm Ecor International’s consideration of its customers, the environment and the working conditions of its employees.

“Obtaining and maintaining certification is an important commitment, which followed a work programme planned at every stage, with a series of analyses, tests and inspections” says Andrea Perezzan, Quality Manager of Ecor International SpA, “necessary to meet the required criteria and guarantee a perfect result. The certifications are not a point of arrival, for Ecor International and all employees they represent an incentive to start”.

System certification

Ecor International’s priorities are therefore the satisfaction of its customers, respect for the environment and the health and safety conditions of its employees.

The Schio-based company’s commitment is to pursue the continuous improvement of products and processes, as well as the efficiency and effectiveness of the Management System certified according to ISO 9001, AS/EN 9100, ISO 14001 and ISO 45001. To this end, Ecor International analyses risks and opportunities and annually establishes measurable objectives consistent with the internal policy adopted and monitors their achievement through specific KPIs.

Below are the system certifications obtained:

1998 – ISO 9001: QUALITY MANAGEMENT

This certification is valid for the following field of application: production and assembly of stainless steel, titanium and special alloy products for the food, medical, chemical and waste treatment industries.

2004 – ISO 14001: ENVIRONMENTAL MANAGEMENT

This certification is valid for the following field of application: production and assembly of manufactured articles in steel and special alloys, through the stages of mechanical machining, welding, chemical and mechanical surface treatments, non-destructive testing, for the food, pharmaceutical, ceramic, chemical, waste treatment, packaging and aerospace industries. Laser cutting of tubes.

2010 AS/EN 9100: AEROSPACE INDUSTRY QUALITY

Purpose: production of welded parts and assemblies in stainless steel, titanium, and special alloys for the aerospace industry.

2013 – ISO 45001: HEALTH AND SAFETY OF WORKERS

This certification is valid for the following field of application: production and assembly of steel and special alloy products, through the stages of machining, welding, chemical and mechanical surface treatments, non-destructive testing, for the food, packaging, chemical and pharmaceutical industries, aerospace.

System Certification

The development of the Aerospace & Defence area would not have been possible without certification of the special welding, heat treatment and non-destructive testing processes used by Ecor International to produce and examine critical components.

The NADCAP accreditation, an acronym for National Aerospace and Defence Contractors Accreditation Programme, is a worldwide co-operation programme of the major aerospace and defence contractors. The aim is to manage a common approach to the accreditation of ‘special processes’ and promote continuous improvement in the aerospace industry by supporting common standards and auditing criteria worldwide.

Gaining the trust and respect of one’s customers is not easy, even more so in maintaining and growing relationships. This is why the skills and work of Ecor International employees have been certified under this important programme.

Below are the process certifications obtained:

2011 – NADCAP WELDING: WELDING PROCESSES

This certification demonstrates compliance and accreditation of the welding activity.

2011 – NADCAP HEAT TREATMENT: HEAT TREATMENT PROCESSES

This certification demonstrates conformity and recognition of accreditation of heat treatment activity, on materials such as titanium alloys, nickel, aluminium and austenitic steels.

2014 – NADCAP NON DESTRUCTIVE TESTING

This certification demonstrates the conformity and accreditation of the non-destructive testing activity, i.e. the set of technical analyses used to assess the properties of a material, component or system without causing damage to it.

“We can only be proud of the certifications we have obtained, especially considering that our projects are carried out entirely in the Schio plant, in the Aerospace & Defence production department” explains Giulio Roana, Aerospace & Defence business unit manager. “But we are able to respond to customers’ requests on time and on schedule, and the Nadcap certifications demonstrate the company’s skills and capabilities and the quality of its working methods”.

@EcorIntern

@EcorIntern