Recently, Ecor Research officially obtained the NADCAP Certification for Non Destructive Test Processes from the Performance Review Institute, confirming the highly specialized skills that the company is achieving also in the aerospace industry.

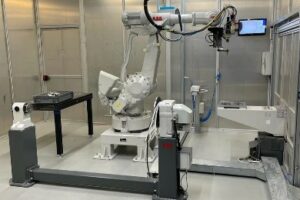

The certification arrived just six months after the installation of the two plants dedicated to the process of Non-Destructive Testing in the production site of Schio (Vicenza). Those tools allow the components inspection via dye-penetration method and x-rays, in order to identify possible imperfections that could compromise their integrity. NDT controls play a strategic role in Ecor Research, ensuring to customers quality and perfect manufacturing on critical components in the aerospace industry such as engine cradle, exhaust nozzle and tube for fluids transportation, guaranteeing the customer a full manufacturing assurance.

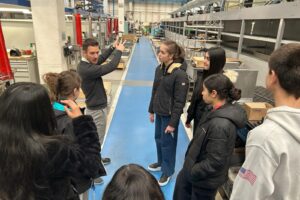

Moreover, are also inspected food industry products such as floats, specific knives and preliminary control of the welds. In the path that led to the certification achievement, two Ecor Research specialized technicians have been involved. They have followed the training courses and passed their exams to be certified ISO 9712 for personnel working in Non Destructive testing and then NAS 410 / EN 4179 for the qualification in the aerospace industry.

“We have set ourselves an ambitious goal -says Eng. Giacomo Cattelan, NDT operator-. We started from scratch, but we have become operative in a very short time. It was not easy, but thanks to the excellent resources, both human and technological and to the synergy within the team, we have achieved a significant result”. Now, the certification for Non-Destructive Processes Control is added to the other two NADCAP certifications obtained for Welding and Brazing Process. With the awareness of the high criticality of its special processes, Ecor Research maintains its commitment to customers to ensure quality, efficiency and reliability.

@EcorIntern

@EcorIntern