Applied research at Il Sentiero International Campus integrates Ecor International’s competences in designing highly critical components.

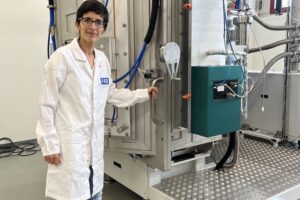

At the industrial research centre, Il Sentiero International Campus, there are engineers and researchers with specialised skills such as Reliability Engineering and Surface Engineering. These technical competences enable the best possible management of innovative production processes such as additive manufacturing or 3D printing.

Thanks to its in-depth knowledge of the additive manufacturing process, Il Sentiero International Campus is able to identify innovative ad hoc solutions, specific for each project.

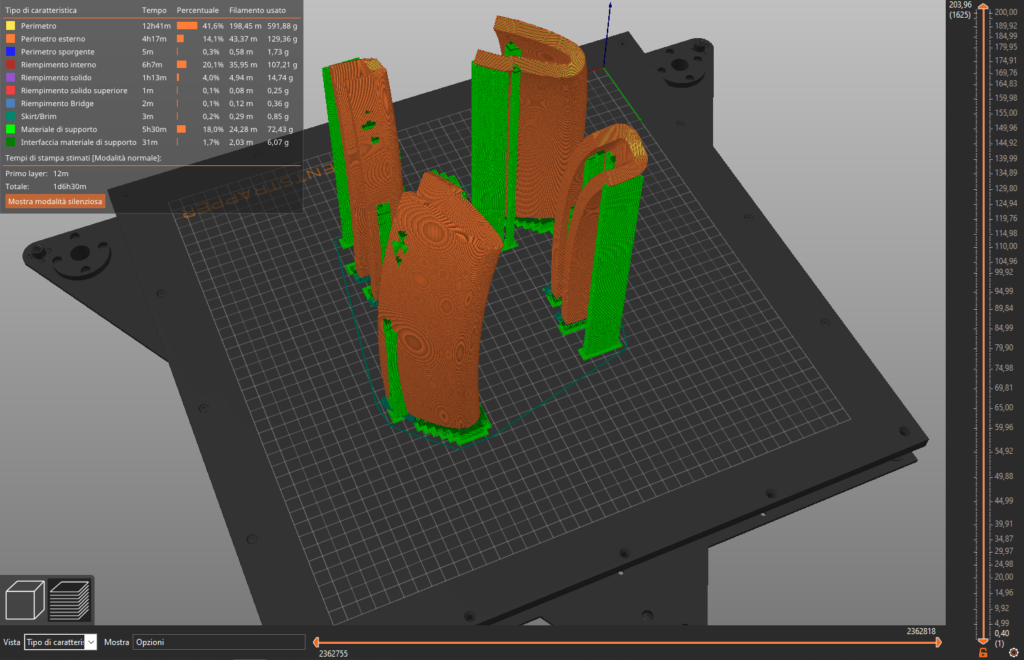

In the production of aeronautical components, for example, the researchers and engineers at Il Sentiero International Campus use 3D printing technology to create verification templates, a faithful reproduction of the part that requires certain precautions.

“We start from the need that the customer brings to us and, thanks to the collaboration with Il Sentiero, we activate a research project to test and to offer the best solution in terms of sustainability and effectiveness,” explains Rinaldo Rigon, Core Processes & Competences Manager at Ecor International. “Components such as those we make for customers who produce aircraft and satellites must comply with strict requirements and follow certified welding processes. They have special requirements such as extreme accuracy in welding, constant control of measurements and shapes, and continuous attention, right up to the final transport phase’.

To meet these challenging objectives, the researchers and engineers at Il Sentiero International Campus support the design department by using 3D printing technology to create functional components for inspection, welding and transport.

Depending on the features of the final part, they first decide which material to be used and the parameters of the additive manufacturing process to be set. To create the 3D piece it can be used plastic or metal, with different thicknesses and densities depending on the processing and surface to be obtained.

By integrating 3D printing into the process, the components manufacturing for the aerospace sector achieves premium results.

Components created through additive manufacturing can have several functions:

– supporting the orientation of two components to be welded in a specific position,

– checking free surfaces,

– packaging for transport safety.

“The design of the 3D printing process is one of the most powerful tools we have to give a customized service to the end customer.

The speed of the process allows us to hold what we design in 3D after only a few days. This is one of the most fascinating feautures of the additive manufacturing.” – explains Mario Franchi, Researcher, Laboratories & Technologies Additive Manufacturing, Il Sentiero International Campus. -“We manufacture pieces that are always different from one another. They are solutions to very specific requirements”.

@EcorIntern

@EcorIntern