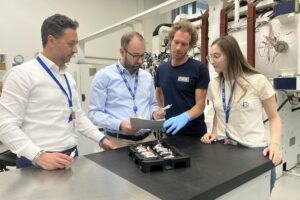

Advanced Mechanics is to Ecor an exciting area to explore that presents committed professionals with new challenges and continuous experimentation to identify the best solutions and therefore meet the clients’ needs.

This particularly flexible business area involves mainly the designing, manufacturing and assembling of components and high-added-value systems. In this field, the company operates, for instance, in the sectors of welded components and pipe production for pressure equipment and pharmaceutical packaging machines, and of vacuum pump components for laboratory equipment.

The other area Advanced Mechanics involves is the so-called test rig, which includes the design and development of customized systems to test clients systems specific components, in order to understand if they comply with given mechanical and resistance requirements. Moreover, test rigs have also to do with the functioning of a machine, complex industrial systems and operating tests. Ecor Research can therefore contribute to process and system optimization not only through test rigs, but also through modeling, virtual simulation and data statistical analysis. Ecor Research is currently supporting companies operating in the railway, cigarette production and high-end jewelry sectors in the development of testing machines. For this reason, these activities don’t concern a specific field, but miscellaneous ones.

Thanks to consolidated knowledge gained by the Company over the years, as well as to the high-level technology available, the Advanced Mechanics Team is able to study and put forward specific custom-tailored solutions and might benefit from future opening up to new sectors. Hence the need to involve professionals with cross-disciplinary skills in several areas: mechanics engineering, chemistry, physics, automation, corrosion, materials science, use of specific software and DOE (Design Of Experiments) analysis. For this purpose, Ecor Research can rely on a network of consultants that share knowledge and skills.

Advanced Mechanics flagship is the TAV 427 high-vacuum furnace our company has been using since 2009 for mass production of components and heat treatment as well, a process the company has been awarded a Nadcap certification for. Components that have to undergo braze welding or specific heat treatments are placed inside the machine, which can be under ultra vacuum conditions and whose temperature can be of up to 1,400°C. What makes it a quite uncommon machine in the Italian and European scene (there is only a handful of such furnaces), is the internal metal coating, made of molybdenum, instead of graphite. The latter, unlike molybdenum, is cheaper but its residues can undermine the cleanliness of processed parts and the quality of the machining.

Moreover, Ecor Research furnace added-value is fully understood if we consider that it is used in the materials research field too.

Advanced Mechanics thus represents a strategic business area for Ecor Rsearch: the consolidated skills of professionals involved and the high-level technological instruments used guarantee a taylor-made and high-value service to clients.

@EcorIntern

@EcorIntern