Brazing is a special process that requires specific skills and experience to be mastered.

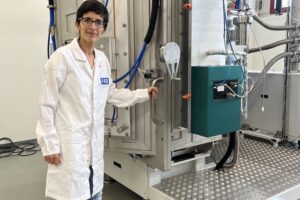

At Ecor International, specific know-how in the vacuum furnace brazing process has been developed over the years. In order to join big and complex parts, an equally big and advanced equipment is required.

A state-of-the-art high vacuum TAV furnace for heat treatment and vacuum brazing, which can reach 1,400 degrees and a high vacuum level, has been in operation since 2009.

Over time, customers in the Advanced Mechanics sector have submitted to us requirements for innovation in the field of joints, aimed at speeding up production, increasing plant performance and reducing consumption.

Starting from the search for increasingly high-performance solutions in response to these needs, Ecor International has often proposed, developed and optimised the brazing process, involving dissimilar materials, even non-metallic ones, such as ceramic or graphite, in combination with precious metals and noble alloys, such as platinum and high-strength nickel/titanium alloys.

By managing customised projects according to customer requirements, many different variables (such as temperature trend, roughness, pressure method, and the most suitable type of brazing alloy) have to be evaluated from time to time.

The study of special brazing processes is possible thanks to the ongoing collaboration between Ecor International’s engineers (who manage and optimise the process) and the researchers at the Il Sentiero International Campus research centre (who combine engineering training with materials and corrosion expertise and carry out laboratory analyses to assess and characterise the properties of brazed joints).

Riccardo Franci, Laboratories & Technologies Director, Il Sentiero International Campus, explains: ‘Our customers are looking for solutions to complex problems that can only be tackled successfully if all the expertise is brought on board.

Each step requires specific know-how in different fields: analysing the problem, studying the literature, selecting the solutions to be adopted, fine-tuning the process and analysing the components in order to evaluate the results. The real strength of the Ecor International Group is working in synergy and considering these skills as a company asset. This asset is what distinguishes us from other realities.

“The integration and collaboration with the Research Centre Il Sentiero International Campus allows us to offer customised solutions,” continues Rinaldo Rigon, Core Processes & Competences Manager, Ecor International. “In this way, we can support customers in their goals of increasing product quality, performance and environmental friendliness, and optimising production costs.

Three examples of research and solutions developed with ceramics:

Following R&D process, Ecor International’s engineers perform the brazing of power electronic boards constructed from ceramic substrates and brazed metal conductive tracks. Ceramic has been tested as a substrate and brazing paste for defining electronic tracks to allow higher currents to flow through the circuits.

Ceramic has also been used in the past by Ecor International to meet insulation needs in scientific experiments conducted by the Spanish nuclear physics institute CIEMAT (Centro de Investigaciones Energéticas, Medioambientales y Tecnológicas).

In this case, the ceramic material was used in a radio frequency application in particle accelerators. The shared research took 2 years to arrive at optimal results.

The latest example of process optimisation leading to a brazed product, at an industrial scale, are feed-throughs. These are high-voltage feed-throughs that Ecor International produces in various types, which must be made by joining different materials. Ecor International has optimised the process to produce metal-ceramic (steel-alumina) joints on a large scale.

Thanks to research and innovation, the Ecor Group is constantly evolving. Its roots are rooted in an in-depth knowledge of steel and extend to other materials such as ceramics, graphite, precious metals and noble alloys.

@EcorIntern

@EcorIntern