The Engineering Department has started a new test in the Verification & Validation Center that analyzes the wear resistance of different material types. Comprehending which is the most durable solution for the use into a Food Industry packaging plant is the objective.

Wear study is one of the strategic activities in automatic machines sector, because plants components wear out over time: understanding if there are materials and treatments characterized by a longer life cycle permits the optimization of the machine maintenance costs.

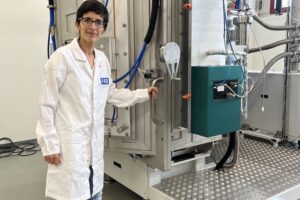

We have asked Pietro Pranovi, Head of Laboratory and Testing, about the contents of this innovative project.

Pietro, which alimentary plant component has required the test?

The component exposed to wear in the plant is a cam, that is to say a mechanical organ with a specific profile whose geometry has to be maintained over time. In the plant, some rolls that are in contact with the cam provoke its wear influencing the automatic machine operation.

Is it possible to postpone this problem?

Yes, we can consider if there are more performing materials both from a structural and technical point of view, but to understand this we have to carry out specific tests simulating the plant working conditions. Therefore we are using a testbed internally projected and produced able to test as necessary wear, corrosion and synergy between the two variables (tribocorrosion).

Which are the main contents of this test?

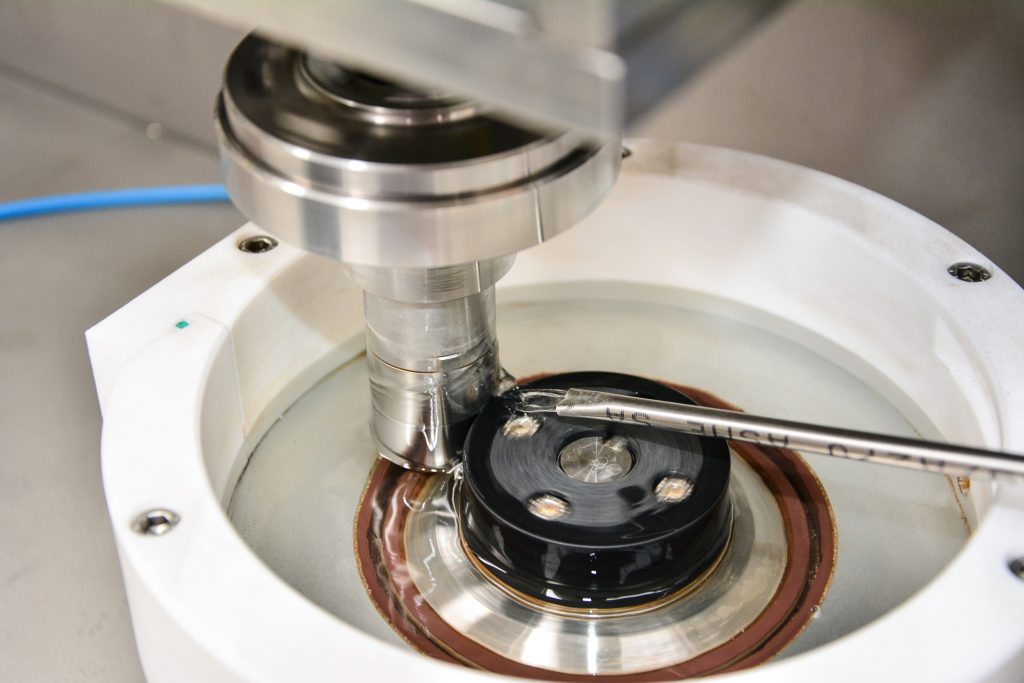

The test that we are carrying out is a wear test ‘’ring on ring’’ on rolling mode. In other words, a round sample of 60 mm is in contact with a steel one of 30 mm (the same material of rolls). The biggest sample is made of a different material depending on the test, which will be used to produce the new cam. The two ‘’rings’’ rotate at the same peripheral speed: thanks to the movement of the two samples in contact, the wear condition is recreated. During the test, samples are immersed in a liquid in order to recreate the plant working conditions.

Therefore you are testing samples produced with different materials, is that right?

Exactly, and this is very important because only comparing the degree of wear of different samples we are able to understand which one is the most appropriate. In particular, we are testing samples of glass-fiber reinforced nylon. Both the direction and type of samples fibers provoke a different resistance. Moreover, we are testing also other typologies of matrices.

How can you evaluate the wear of samples?

After 30 hours of test for each sample, we measure its weight and diameter comparing final and initial values. During this process, we consider also that the matrix material, absorbing water, expands reducing its resistance. Comparing the different materials, the individuation of the less worn out one and therefore the most resistant will be possible.

TO KNOW

-

Tribocorrosion is the science that mix the study of superficial interactions between organs in relative motion, including friction and wear (tribology), with the study of the deterioration of a solid and metallic substance in an aggressive environment (corrosion).

@EcorIntern

@EcorIntern