Companies operating in aseptic food packaging are particularly attentive to the phenomenon of corrosion and mechanical wear that contribute to the degradation of components and machinery. High performance is expected from the parts that come into direct contact with the product during processing.

The Ecor Research Engineering Department has already designed and built test rigs that can provide information on these two aspects. So far these two fields have been evaluated through the use of two different test rigs.

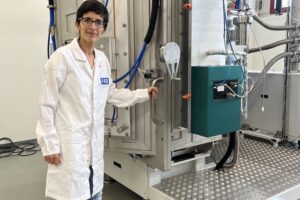

The company is now making another step forward by designing, building, commissioning and testing a test rig that can test both mechanical wear and corrosion at the same time.

This is a challenging project whose realisation is a challenge for the team of engineers and which sees the participation of the Mechanical Engineering Dept. at the University of Padua led by Prof. Manuel Dabalà. The test rig will be able to evaluate the tribocorrosion behaviour of components. Tribo-corrosion is the science that studies the synergy between tribology, i.e., the study of the aspects typical of mechanical wear, and corrosion, i.e., the evaluation of the resistance of the metal materials in an aggressive environment.

The test rig will be able to replicate both the real operating conditions and recreate the most aggressive conditions to accelerate those degenerative phenomena that become manifest spontaneously only in the long term. In order to carry out these tests, a component undergoes a relative cyclical movement compared to a counterpart in aluminium oxide, while immersed in an electrolyte. Electrochemical measurements make it possible to evaluate the progress of component degradation.

The final objective of the project is to determine the synergy between mechanical wear and corrosion when these contribute simultaneously to the degradation of a component and therefore to provide specific and strategic information instrumental to making a more knowledgeable choice of the materials to use. Once the optimal solution is identified, it will be possible to extend the life of a component, ultimately optimising the costs of a system.

@EcorIntern

@EcorIntern