In the industrial production field, technological development activities move towards a precise direction: the production of more and more light high-performing components, thin and with low environmental impact. In short, this is the activity known as “lightweight design”, the light design of components.

This new initiative, just started, will allow offering technological solutions and innovative materials useful in the transport and mechanical fields.

We are speaking about the “GAP project, high-performing cast irons and aluminum alloys for innovative components’’, in which some Sinfonet (Smart & innovative Foundry Network) partners participate.

Sinfonet is one of the Regional Innovation Networks in Veneto region, related to the Smart Manufacturing area. It is composed of companies and Universities (among them Ecor International) that collaborate in research, innovation and technological transfer activities applied to foundry.

THE PROJECT

GAP partners plan to develop innovative materials, cast irons and aluminum alloys with better characteristics in terms of mechanical properties, corrosion and wear resistance.

These materials could be usable in many fields and in particular in the transport (automotive, naval, rail systems and road transport) and mechanical ones. In fact, in both these fields, lighter components mean more efficiency and lower costs, as well as lower consumptions, thanks to a more rational use of energy and resources with a positive impact on the environment.

For GAP project, the current budget is more than 2.400 million euro. The amount is partially financed by the announcement supporting research and development projects proposed by Industrial Districts and Regional Innovation Networks (Regional Development European Fund 2014-2020 of the Veneto region).

Some Sinfonet companies will participate: Ecor International, Fonderia Corrà, Rds Moulding Technology, Enginsoft, Zanardi Fonderie, Italker, Unilab Laboratori Industriali, Fusina Rolling, Lino Manfrotto and the Industrial Systems Management Department of Padua University (that coordinates the project).

The ‘’GAP’’ kick-off meeting was held in March in Ecor International headquarters. Research activities conclusion is scheduled for the end of 2019.

PHASES

In the first phase, the project will focus on the metallurgical design, in other words a preparatory study for alloys development aiming at defining properties linking them to material chemical composition.

This will be the starting point for the second phase: the production of prototypes based on innovative materials composition found out before. On one side, we are dealing with different innovative cast iron sample typologies, heat-treated and characterized by a high percentage of silicon and/or compact graphite. On the other side, samples will be produced also with aluminum alloys.

The third phase focuses on materials characterization, which is the study of materials properties aimed at understanding mechanical characteristics, wear and corrosion resistance, ease of welding. A series of experimental tests (for instance non-destructive tests) will be carried out, microstructure (use of optical and electron microscopy equipment), mechanical behavior, wear and corrosion resistance. Tests results will be useful in order to understand if materials match target parameters. Otherwise, the team will have to identify corrective actions to apply in order to improve performances.

Lastly, Sinfonet will compare conventional materials with innovative ones developed in the project, proposing a summary of mechanical, microstructural and technological characteristics. Moreover, Sinfonet will elaborate the modalities that will allow concretely introducing these materials in industrial processes, highlighting also some case studies.

ECOR INTERNATIONAL’S ROLE

Competences shared by Ecor International in the network are materials science and related research activities.

First, the company will study alloys ease of welding by means of welding tests, metallographic tests and related control methods. This will help in understanding if materials can be really used in production processes and which is their integration level in current process/product systems.

After, Ecor International will focus on coating design and the development of innovative materials functional coatings in order to create the appropriate surface properties, whereas the substrate will have the function to maintain mechanical resistance properties.

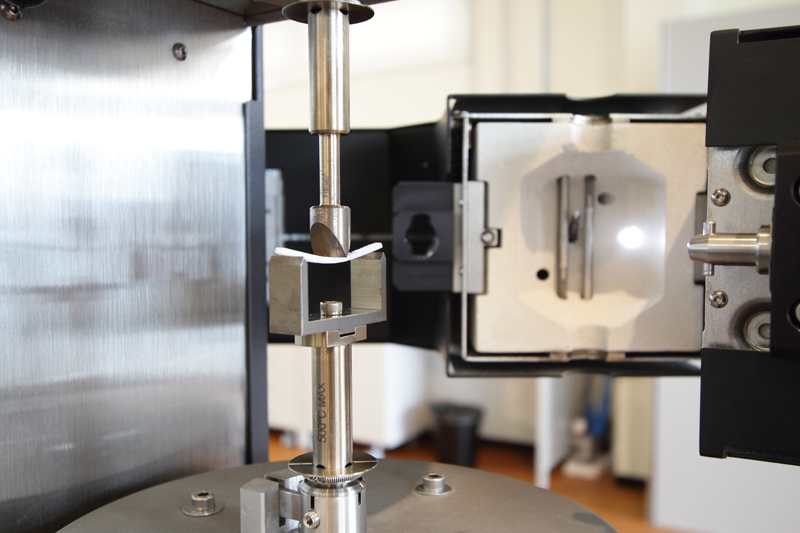

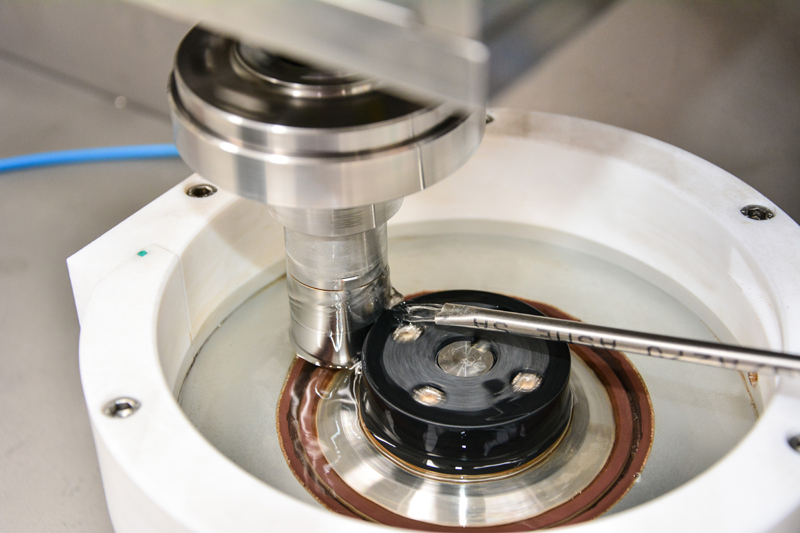

Finally, one last activity is the assessment of wear-resistance using a test rig designed and built by Ecor International, which can simulate, depending on needs, wear, corrosion and the synergy between these two variables (tribocorrosion).

TO KNOW

- Regional Innovation Networks are systems consisting of corporates and private/public entities, present in the Region but not necessarily contiguous in terms of territory, which work in different fields and are able to develop a group of initiatives and projects relevant for the regional economy.

- Smart Manufacturing is an integrated and collaborative production system that uses advanced information and production technologies to encourage physical processes flexibility reaching the global market.

- Cast iron is an alloy composed of iron and carbon. The presence of the second element is between 1,9 and 6,5%.

- An alloy is a material composed of two or more chemical elements.

- Metallurgical design is the design of the chemical composition and process leading to the development of the subject material of a research.

- Materials characterization is a series of processes through which we analyze specific properties. It includes for example: microscopic and spectroscopic tests, mechanical and corrosion tests.

- Coating Design is the design of surface treatments on materials aimed at improving performances. Generally, these treatments consist on modifying the surface chemical composition and/or mechanical/physical properties (i.e. hardness). They can be obtained thanks to propagation treatments of specific elements on the surface or positioning on the surface itself some layers characterized by different thickness according to the deposition technology used.

- A test rig is a machine able to reproduce mechanical systems functions. It is designed and built to test specific components, in order to understand if they meet given mechanical and resistance principles.

@EcorIntern

@EcorIntern