Sommario

Pharma Division: Ecor International’s expertise

Ecor International has been present in the pharmaceutical industry for about seven years, developing, designing, and manufacturing critical components and complex systems for filling and packaging machines.

Thanks to the global experience gained in almost 50 years of activity, the Vicenza-based company can propose customized solutions in synergy with customers, optimizing plant layouts and improving process flows.

It manufactures products that comply with the ASME-BPE standard, even with very small thicknesses and diameters and roughness of fewer than 0.38 microns, guaranteeing accurate controls at all stages of processing.

A partner you can rely on

The Pharma division is primarily aimed at companies that manufacture packaging, filtration or formulation machinery for pharmaceuticals and derivatives, both in Italy and abroad.

State-of-the-art production technologies, final quality controls and at different stages of progress, process control through continuous monitoring allow achieving high-quality standards of the products. Every activity, from the sampling of the raw material to the production and control of the finished product, is traced through an automatic system that ensures complete product traceability, guaranteeing a high level of attention to the quality of the product itself. But reliability often comes from the early stages of product design, and this is where Ecor International is focusing its strategy.

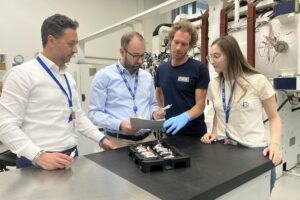

“Ecor wants to be more and more a strategic partner for its customers. It wants to take collaboration to a higher level than the common ‘supplier-customer’ relationship. Thanks also to the group company Il Sentiero International Campus, we can support our customers right from the initial development of their products, accompany them to the definition of the project, create prototypes, and above all test them using rigorous methodologies that follow the rules of reliability engineering. Finally, we manufacture the products using the most advanced production technologies” explains Fabio Pozzebon, Head of the Pharma Division.

Thanks to this experience, Ecor International’s Pharma Division is now recognised by its client companies as a reliable partner to refer to.

The start-up that wants to change the methods of industrial filtration, washing and drying

This is how he met a start-up company with which he began to collaborate on a project for an innovative filter in the pharmaceutical sector to separate solids from liquids.

“PWD Industrial Filtration is a company operating in the industrial filtration, washing and drying sector with applications in the pharmaceutical, chemical, food and beverage fields” says Fabio Pozzebon.

To develop this innovative filter, in 2019 PWD Industrial Filtration received a grant from the European Commission, under the prestigious SME Instrument Phase 2 Programme, and in 2021 it entered a number of collaborations with strategic partners, including Ecor International, for some specific activities.

“Ecor International and PWD share ambitious goals, such as revolutionising the way industrial filtration, washing, and drying is performed. PWD approached us for support in the production and assembly of the PWD Laboratory Filter and Pilot version” says Pozzebon.

“We are an Italian start-up company bringing innovation to the field of filtration, washing and drying in the pharmaceutical industry” says Igor Klewicki, CEO of PWD Filtration.

“Ours is a highly diversified team composed of experts in different fields (R&D, technical operations, business development, etc.) supported by ambitious young professionals working with a highly entrepreneurial spirit. Our mission is to revolutionise the way industrial filtration, washing and drying is carried out today. Our technology has been patented in 8 countries (AT, CH, DE, FR, GB, IE, IT, NL) and is primarily aimed at users of industrial filter/dryers” continues Klewicki.

“We have key people in the company who deal solely with R&D. Our expert team deals mainly with process innovation and mechanical design tailored to the needs of users (over 95% of components are made completely in-house).

Our team of experts focuses on process innovation and mechanical design tailored to the needs of users (more than 95% of the components are made completely in-house). Our technology reduces the use of chemical solvents during the washing process by 50%. Thanks to an innovative compound drying process, we achieve a reduction in drying time of more than 50%. The efficiency achieved in the drying and washing processes in the production of special compounds (in particular, active pharmaceutical ingredients and fine chemicals), makes it possible to reduce the amount of chemicals in the environment and the amount of energy consumption and therefore the level of CO2/GHG emissions. PWD technology is also in line with Industry 4.0 as it is highly automated and, as a result, equipped with various sensors that allow detailed information to be collected during the processes of industrial filtration, washing, and drying of chemical compounds” Klewicki continues. “We would like to thank all our strategic partners for their support and, in particular, ECOR International whose role has been crucial in this crucial scale-up phase”.

Industrial filtration/drying to date

The market for industrial filtration, washing and drying is dominated by Nutsche technology (filtration, washing and drying) and centrifugal technology (filtration and washing). These technologies originated in the 1970/80s and are therefore not protected by patents. Since 1970 there have been very few innovations in industrial filtration, washing and drying processes. Demand and production requirements, especially in the pharmaceutical and chemical fields, have changed dramatically over the years and this situation has made Nutsche technology highly inefficient and therefore unable to meet current market needs.

Here are the critical points of the prevailing technology that PWD can reduce significantly:

- an intensive use of solvents, chemicals and cleaning consumables;

- a high consumption of energy (in contrast to regulations aimed at reducing emissions from industrial processes);

- a loss of the final product of up to 2%, which affects revenues;

- a difficult processing of the crystals that causes a reduction in efficiency, time, and costs necessary for installation and maintenance.

These aspects cause processing times and operating costs to increase over time and, further, have a significant environmental impact.

The advantages of the innovative filter

What are the innovations brought by the new filter, which is now being tested at industrial level and in an operational environment with potential users?

“Ecor International’s support in this project has helped to bring a winning idea to industrial scale, reducing criticalities and proposing tests to assess and improve the product’s life-time, thus creating a solution with considerable added value for users and above all satisfying the needs of our customer, who for us is more of a Partner”, explains Fabio Pozzebon.

Thanks to the experience and skills of Ecor International’s Pharma division, it has been possible to achieve the result desired by PWD Industrial Filtration, which can now present an innovative filter capable of bringing the following advantages:

- Operational:

o reduction of space and labour requirements;

o reduction of losses of finished products;

o optimisation of production costs. - Economic:

o reduction of investments in terms of CAPEX;

o reduction of costs for consumables, labour, energy;

o increase in revenues;

o cost optimisation with respect to prevailing technology. - Environmental:

o reduction of processing times (pressing, drying);

o reduced energy requirements;

o less use of solvents.

Filter application areas

The PWD technology consists of an innovative filter/dryer, intended for applications in industrial filtration/pressing (P – Pressing), washing (W – Washing) and drying (D – Drying) of various types of end products, from active pharmaceutical ingredients (API) to chemicals (fine chemicals) to various compounds in the food and beverage industry.

This innovative filter/dryer operates in a closed environment with all functions performed under pressure or vacuum, where the separation of solids (high quality product) from liquids (solvent or washing solution) and the drying of solids, is performed autonomously without the need for human interference.

Ecor International in favour of the environment

This solution introduces a new state of the art in industrial filtration and drying, offering unparalleled advantages in wide operational flexibility.

With this new solution, Ecor International demonstrates its sensitivity to environmental issues, making another important contribution. In fact, this is not the first time that the Schio based company is involved in a project with environmental issues, because the industrial research centre Il Sentiero International Campus cares about things inside, but also outside the building.

@EcorIntern

@EcorIntern