Sommario

Ecor International Spa has participated and contributed to the implementation of the TEMART project -called by the Veneto Region and allocated over 2 million euro from the European Regional Development Fund- characterized for study, development and validation of innovative technology applications capable of prototyping and producing artistic and design components and products combining the qualities of form and material with multifunctionality which, in most cases, is attributable to the nature and quality of the surfaces, with particular relevance for the application of additive manufacturing technologies for an extended range of materials (polymers, composites, metals, ceramics and cements) and their combinations in the same artifact.

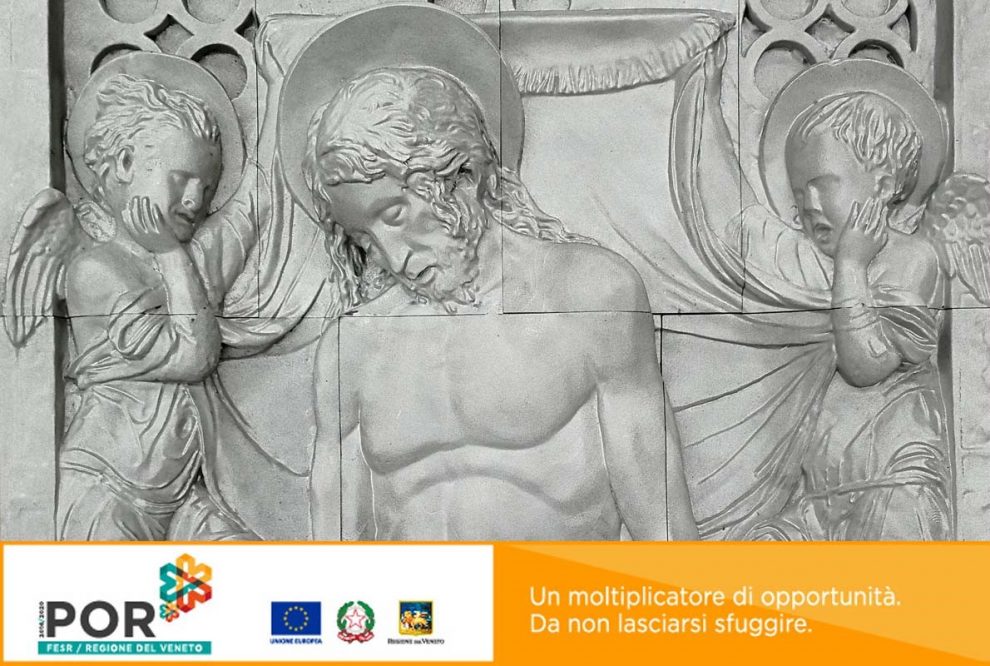

This challenge picks up skills to 360°. Artistic knowledge and skills are combined with technical and scientific skills to give shape and develop new aesthetic and material frontiers. In particular, in this phase, we focused on the reproduction of a bronze relief of Donatello inserted in the altar of the Basilica of Sant’Antonio in Padua not accessible to the general public.

The contribution of Ecor International

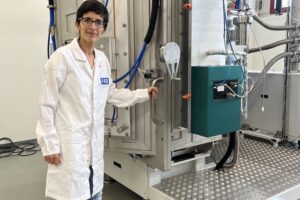

Within the project, Ecor International SpA actively contributed to the project by providing a wide range of knowledge and skills in metallic materials. Through laser scanning of the work it was possible to create prototypes in AISI316 stainless steel. The use of this material made it possible to experiment with different methods of post-processing surface finishing treatments, obtaining diversified tactile yields in line with the needs of the case. Producing the reproduction in stainless steel with these particular specifications has also guaranteed the tactile use of the surface in highly hygienic conditions, allowing the appropriate surface sanitization processes to be carried out without degrading the material itself thanks to its particular resistance to chemical agents.

As reported by researchers who have worked on the study, «The choice of AISI316 stainless steel represents for Ecor International the possibility to use their skills in the food field -in terms of Hygienic Design- for decidedly different contexts. The possibility of proposing a re-interpretation of a work of art of great value in an innovative version and in conditions of hygienic safety demonstrates the wide versatility of surface finishing treatments in the adoption of sanitizing treatments. “

All this has made it possible to further show the technical versatility of stainless steel outside of traditional operational contexts.

A social implication

The reproduction of the low relief of Donatello in stainless steel, however, has not only testified to the technology put in place by Ecor International. In addition to the hygienic safety of the AISI316, the main research work consisted in the study and refinement of the surface functionality of the material. The low relief of Donatello was worked to be usable and enjoyable even to a visually impaired audience through different surface finishes that have allowed, for example, hair, clothes and faces to give different tactile perceptions in order to allow a functional reading to the recognition of forms to the visually impaired.

The optimization of surface treatments was made possible by voluntary collaboration with the project of Mrs Sabrina Baldin, blind and always active in cultural and social projects for the blind. She was involved in part of the research for the tactile assessment of surfaces and, as she said during the collaboration with the Ecor International team, «It is a project of high social value. We appreciate the sensitivity in the development of projects of this type that have not only a high cost at an economic level but that require a great commitment in terms of skills and human resources. As impact is something very important because at the level of accessible culture there is really little attention to our daily difficulties and not being able to enjoy these works of art is a great regret. In Padua we have everything under glass and therefore not perceptible with hand. Who does not see anything is forced to trust the eyes of others».

Therefore, not only a great technological and artistic result but also and above all of a social nature in which art is transformed into a work of inclusivity and makes it open itself to an ever wider audience in the message that is proper to the artist who creates to communicate to a public “simply” the recipient of the work.

Last but not least, the achievement of objectives that have an impact on citizens in accordance with the targets of the nascent Horizon Europe program for a concept of research “by and for the citizens”.

Future developments and partners

Within the TEMART project, the partners have been multiple and each one has been asked for research, study and realization skills. Besides Ecor International Spa, University of Padua, the University of Verona, the Ca’ Foscari University of Venice, the company Prismatech, Metal Finish Srl and the Venetian Heritage Cluster Srl collaborated to the project.

@EcorIntern

@EcorIntern