In an ever-changing world, internal training is one of the fundamental elements to encourage the acquisition of knowledge and skills marketable in employees’ daily work.

In this perspective, Ecor International has decided to invest in training and, thanks to the approval of the project “Lean Strategies and digitalization for the business development of Ecor International” (code 4957-0001-1010-2019), funded by the Veneto Region under the Regional Council Deliberation 1010/2019, has launched a series of internal training courses to implement lean company management. Greater competitiveness will be achieved thanks to the enhancement of human capital by updating skills and knowledge.

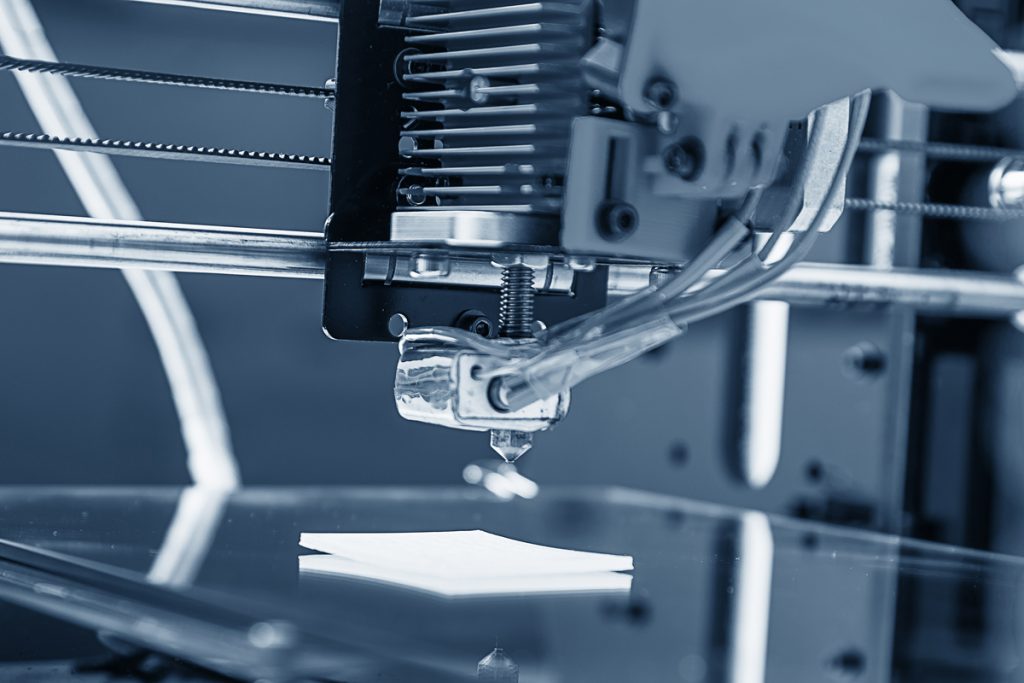

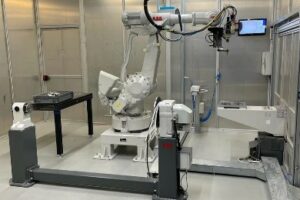

The project, following the Welding Academy, was born from the need to modernize and redesign internal production or organizational processes. A part of the courses is also dedicated to Additive Manufacturing, technology on which the company is increasing its knowledge, with the aim of analysing the complexity of the product, evaluating production techniques with the estimate of cost / benefit ratio and measuring their efficiency.

The general objective is to support the development of managerial skills and the competitiveness of the company to improve the knowledge and skills related to digital transformation. The company will then be able to reorganize its production and organizational processes to increase efficiency and flexibility and meet the needs of the market and customers seeking greater product customization.

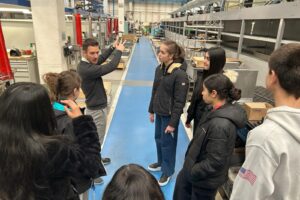

30 employees from the management, commercial, production and logistics areas will attend this internal training on “Lean and digitalization strategies”, for a total of 152 hours. They can acquire technical knowledge to better adapt their work activities. In detail, there will be five classroom-taught lessons, an individual coaching day for every participant and an external activity to motivate the group that takes care of the Lean. All interventions will be held by teachers qualified on specific topics.

@EcorIntern

@EcorIntern