Sommario

Complex products for complex contexts

Throughout its 50 years of activity, Ecor International SpA has always considered quality and reliability pivotal elements in the design and manufacture of its components.

The growing request of increasingly high-quality products in order to comply with international regulations, has deeply changed the project context. Product and process safety have become essential features in ultra-specialised sectors, necessary to guarantee the highest level of safety and hygiene for the community.

Furthermore, the commitment towards these features has led to the creation of custom assemblies and complex products, used in a variety of production requirements, all of which are particularly critical: every part is produced to work properly in complex industrial contexts.

Therefore, each product is designed with different characteristics to provide the best performance. Consequently, there may be different materials, mechanical strength characteristics, tolerances and roughness depending on the situation and on the application.

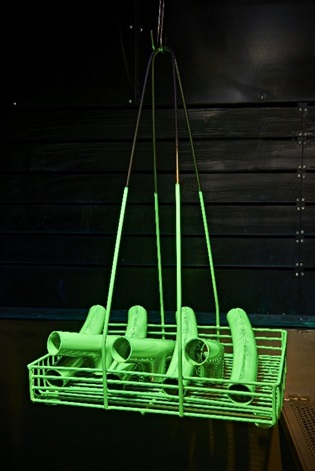

A tough working environment

In the pharmaceutical and food sectors, ensuring the highest possible level of safety is not only a necessity but a duty, the degree of difficulty is also a relevant factor. Nevertheless, Ecor International work with a spirit of challenge and enthusiasm in synergy with our partners to provide the best possible solutions.

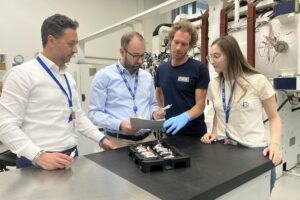

All this is made possible by the skills and experience of our engineering department, which consists of more than 25 people including mechanical, mechatronic, materials and design engineers.

The know-how we have acquired enables us to provide the best, tailor-made solution for our customers by guaranteeing, depending on the market, a wide range of inspections and certifications. These include, for custom assemblies and complex products, dimensional testing with cutting-edge measuring systems, pressure and vacuum testing at different pressures and with different instruments, dye penetrant inspection and X-rays.

These tests are carried out completely in-house so that we can ensure maximum control at every stage and find any possible fault immediately. Furthermore, we can manage special tests through a high-level network that allows us to maintain strict standards throughout the design and production phases and deliver the best possible product to our partners.

Assembles and complex products: the competences

To manufacture custom assemblies and complex products with a high technical gradient, it is certainly essential to know and to be able to use the best technologies available on the market. Nonetheless, this is not enough. Making critical elements requires a great deal of experience and knowledge of materials as well as production processes.

At Ecor, many manufacturing skills are implemented, including welding, bending and brazing. Welding, in particular, is carried out for complex products, preferably by laser, because it limits material deformation while maintaining its physical and mechanical properties.

Among the most widely used and requested materials by our customers are AISI 304 or 316 stainless steel, alloys and nickel, titanium and aluminium. As mentioned above, each aspect is characterised and chosen in relation to the customer’s needs and the technical requirements with which the product must comply.

@EcorIntern

@EcorIntern