How long is the wheels lifespan in the internal logistics sector? Which factors determine their wear? To what extent have they an impact on the wheels duration?

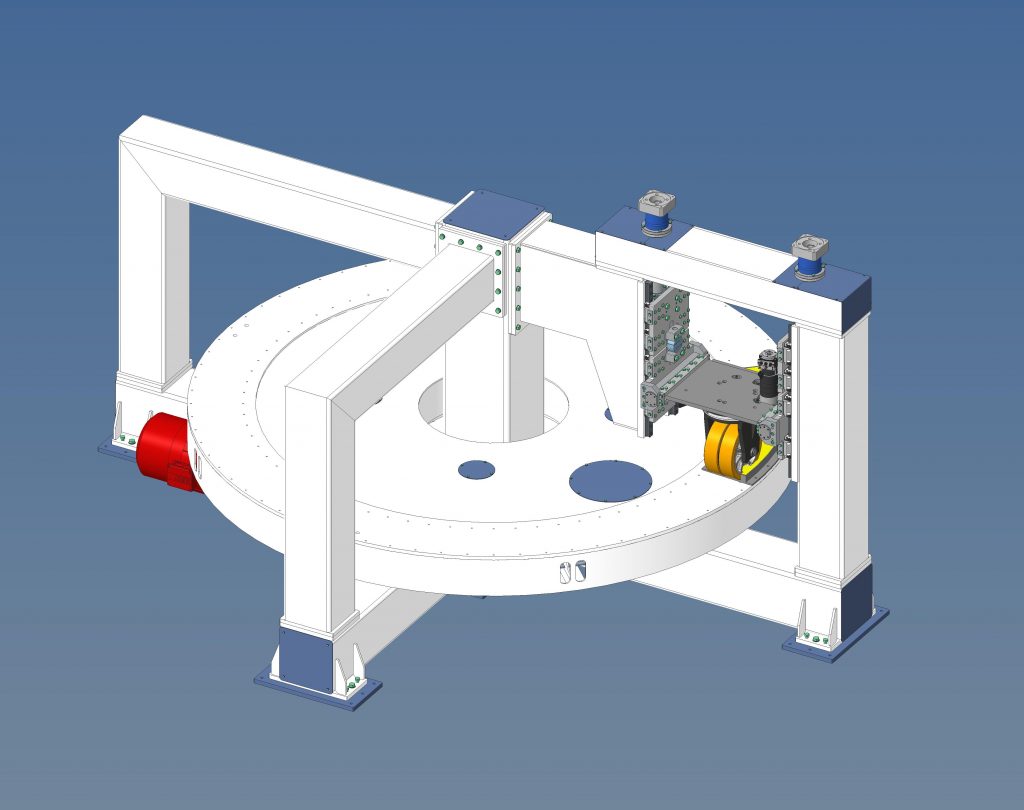

Elettric80 R&D engineers will try to answer to these questions thanks to the designers of Il Sentiero International Campus who are producing a new large-scale test bench: it will enable the test of the wear of polyurethane wheels used by Elettric80 LGV (Laser Guided Vehicles) for the warehouse logistics sector.

Elettric80, a 40-year of experience company specialized in the development and management of automated logistic solutions for daily consumer goods manufacturing companies, has started this project as part of a wider initiative, undertaken with the contribution of Emilia-Romagna Region to study innovative solutions capable of addressing the needs of new generation automatic warehouses.

The company, has expressed the need to carry out wear tests on the wheels of its own LGV (Laser Guided Vehicle). These are innovative and completely automated vehicles moving around warehouses and distribution centres, without any operator on board, ensuring extremely high levels of reliability, precision and traceability of operations.

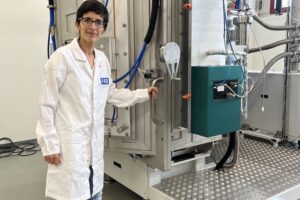

Il Sentiero International Campus has already worked on component wear assessment projects, as we have seen in this article. However, what the designers of the Research Centre are asked to develop is the largest test bench ever conceived. In fact, it will have an estimated weight of 14 tons and will consist of a circular revolving table of over 4 meters: the wheels to be tested will move exactly along that circumference at a speed that can reach 5 m / s.

Why are such large-scale dimensions necessary?

The reason lies in the need to acquire the most reliable data. In fact, thanks to the dimensions of the circumference, the wheels will be able to travel, during the test phase, a simulated route close to the actual conditions of use and this will allow more precise mathematical calculations and therefore to obtain more reliable data.

The ultimate goal is to understand if and to what extent wear is influenced by input parameters (e.g. speed), test bench material, wheels different dimensions and load. Results of future tests obtained, through statistical considerations deriving from the Design of Experiment (DoE), will be the starting point to begin studies aimed at understanding how to improve maintenance and design of vehicles by acting on the factors causing components wear.

The project includes sizing, structural calculation (through FEM analysis), realization of the final design and production and testing to verify whether the machine meets the needs for which it was conceived.

The Design and Prototyping, Automation and Assembly Departments of Il Sentiero International Campus, in collaboration with the designers of Elettric80 will be involved in this components wear test project.

@EcorIntern

@EcorIntern