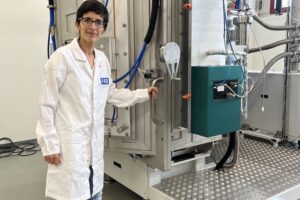

Thanks to a collaboration with Padua University Department of Industrial Systems Technique and Management, Ecor International is increasing knowledge of additive manufacturing for stainless steel alloys, massively used in Food industry. Very significant study for the company that will exploit results in the use of two new plants for special components production.

The research analyses process parameters that influence final quality of a component produced with additive technologies. In particular, the study takes into account SLM Technology (Selective Laser Melting), process based on metal powders layers addition by means of laser melt.

The project concerns the characterization of many samples produced through SLM with different 3D printer settings. In other words, structural, microstructural and mechanical characteristics have been monitored to describe samples properties.

In detail, modified parameters of 3D printer have been laser power, speed of laser beam scan and adding layers thickness. Samples tests have focused on structure study through optical microscope, roughness check, material microhardness study, porosity check, tensile, resilience, fatigue and corrosion tests.

The study has revealed that the thinner the metal layer is, the more reduced and acceptable roughness is, in other words, there are less superficial irregularities. Therefore, layer thickness influences sample surface finishing.

The research has pointed out the big potentialities of additive technology carried out with metal powder and, in particular, Selective Laser Melting technology with stainless steel AISI 316L powder.

In fact, some mechanical properties such as yield stress are comparable with or superior to the ones of parts produced through traditional production technologies. Moreover, additive manufacturing almost completely eliminates technical constraints of objects geometries. This aspect permits, technically and functionally, the production of performing goods.

In the near future, other metal alloys will be analyzed: nickel, titanium, cobalt and aluminum based alloys.

Additional Ecor International studies will take into account analyzed components redesign to maximize SLM technology potentialities.

TO KNOW

- Alloy is a material composed by two or more chemical elements.

- Selective Laser Melting is a particular additive manufacturing process that uses a high power laser beam to melt metal powders.

- Material characterization is a set of processes by which we investigate specific properties. Among these processes: microscopic, spectroscopic, tensile and corrosion tests.

- Yield stress is the tension value in which a material begins to plastically deform switching from a reversible elastic form to an irreversible deformation.

@EcorIntern

@EcorIntern