Since 2014, Ecor International has been part of PoEMA, Polo Europeo Microfusioni Aerospaziali (European Aerospace Casting Centre), a network of companies working together and aiming at improving quality, performance and efficiency of aircrafts engines and turbines components of civil aircrafts, reducing in this way their consumption. The leading society is EMA, company owned by Rolls Royce and main manufacturer worldwide of casting components for aeronautic and industrial gas turbines. Every member of the network commits itself, each one for its own technological and industrial competences, to develop and create industrial processes for the production of rotor and stator blades made of superalloy.

For this reason, in Morra de Sanctis (Avellino), a center of excellence for casting technology as well as processes connected to the development of advanced systems has been created. The other companies involved in PoEMA network are E.M.A. S.p.A., Flame Spray S.p.A., Re.I.M. S.r.l., Strazza S.r.l., O.M.I. S.r.l., Aviotecnica S.r.l., Mosaico Monitoraggio Integrato S.r.l., Tecnologica S.r.l., Officine Di Matteo S.r.l., Rina Consulting-Centro Sviluppo Materiali S.p.A., L’intesa Soc. Coop. A r.l., Bytest S.r.l., Altergon Italia S.r.l., Salentec S.r.l., Bper Banca S.p.A.

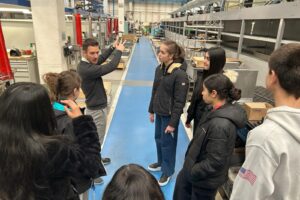

We asked Ilaria Fierro, R&D Project Engineer in Ecor International Campanian site, to tell us about the development of this project realeted to Aerospace&Defense.

Ilaria, which is the contribute Ecor International makes in the network PoEMA?

«We are involved in manual TIG welding of small components called “plates” on stator blades that compose turbines and are made of Nickel superalloy. Moreover, the project aims at studying and developing innovative laser technologies as well as connected automation systems».

What is the status of this activity?

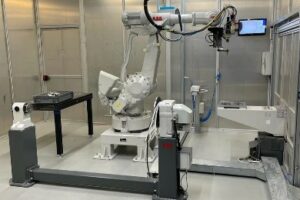

«Recently we have installed in Morra de Sanctis site a fully automated robotic laser welding work station. The laser process is an innovative energy source for welding of superalloys and it will allow increasing welding process efficiency saving not only time and costs, but also obtaining better weld beads. Currently, we are carrying out plant start-up, programming and improvement phases. The short-term aim will be the manufacturing, through laser welding, of the first items requested by customers».

Are there other activities planned for the future?

«In the medium-term, we are going to start repair welding activities, necessary to remove casting-related defeats. Ecor International will develop also a line of penetrant liquids for non-destructive post-welding controls».

@EcorIntern

@EcorIntern