Sommario

A new test rig and especially a new methodology of analysis will enable objective and effective evaluation of stainless steel surfaces for food industry cleanability.

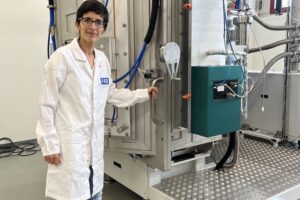

It is the result of the synergic work carried out by a team of both Ecor International and Il Sentiero International Campus researchers, project managers and laboratory technicians, in particular Alessandra Bellucci, Fabio Battistella, Gregorio Carolo, Domenico Stocchi and Silvia Tiberi.

Recently, the results were presented at the Third International Conference on Applied Sciences, held in Parma.

This procedure, that could be used to support the automatic machines cleaning cycles development, was created within the framework of the TresClean project, explained in this article: the high throughput laser texturing of self-cleaning and antibacterial surfaces aims to develop, through laser texturing treatment, antibacterial and self-cleaning food contact metallic surfaces.

With a 3.3 million euros fund, the project has been promoted by the Photonics Public Private Partnership, as part of the H2020 Industrial Leadership program notices. Together with Ecor International and Il Sentiero International Campus, also the University of Parma, the Universitaet Stuttgart (Germany), the Centre Technologique Alphanov (France), the Raylase AG (Germany), the BSH Electrodomesticos Espana SA (Spain) e the Kite Innovation Limited (UK) took part in the project.

The problem

Nowadays, the topic of the hygienic condition of food contact surfaces in automatic machinery is particularly critical, especially in this sector, where it is fundamental to guarantee the consumer safety. Therefore, regular cleaning is required, in order to prevent the formation of microorganisms that could potentially contaminate the products.

The project partners investigated in order to understand how the surface cleanability changes with the variation of its morphological properties. In particular, they have analyzed texturized samples on which several rough microtopographies were recreated: those microtopographies are specifically designed to minimize the contact area between the surface and the substances, therefore to improve cleanability.

The methodology was implemented on the basis of CIP – namely (Cleaning in Place) industrial cleaning procedure, rather than on laboratory investigation techniques.

Due to the complexity of its composition and to the importance of the dairy industry, the focus was on milk contamination.

The test rig

How was it possible to assess the level of surfaces hygiene?

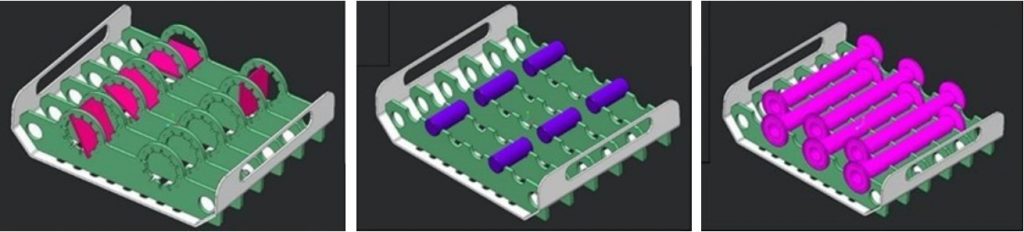

First of all, researchers designed and created an ad hoc test rig, able to simulate the contamination phase and the cleaning phase of an automatic food machine during operation. The test rig is composed by some specific features, such as:

- a module for sample contamination;

- a test chamber for sample drying and cleaning;

- a system for evaluation of the surface cleanliness.

Experimental study and results

The team has conducted several tests on stainless steel samples, each one with a different surface morphology and by using different types of milk.

As a first step, the surfaces of the different samples were stained through a dosing system with a drop of milk, in order to reproduce similar to the real ones contamination conditions. Afterwards, the surfaces were dried and tilted before the cleaning phase: by doing so, through the application of a jet of hot air and monitoring of temperature through sensor, they simulated the curved surfaces contamination during the food equipment operation.

In the second phase, samples were cleaned using nozzles able to simulate industrial cleaning procedures.

Finally, the last step is the evaluation of surface cleanliness, made using a stereomicroscope for a visual inspection and a software for image analysis. Organic contamination was measured instead by detecting the presence of specific substances that could be associated with the metabolism of all living organisms (ATP).

Conclusions

“Collected results may indicate the tendencies related to steel surface cleanability – team members explained. – We have demonstrated that the developed experimental procedure is able to standardize the surfaces contamination phase, therefore ensuring replicability as well as an accurate quantification of soiling on the sample”.

Furthermore, our knowledge of this crucial topic for the food sector has improved. “An effective industrial cleaning procedure depends on the knowledge of how mechanical, thermal and chemical processes work on different types of soiling, and how it is possible to optimize their interaction –researchers said. – Moreover, the steel morphology modification could influence its cleanability. The developed methodology of food industrial surfaces analysis could be a helpful tool to define a proper setting of cleaning procedure parameters and to optimize the quality of steel surfaces, aiming to ensure the high cleanliness standards required as well as to reduce the environmental impact of cleaning cycles.”

@EcorIntern

@EcorIntern