The new “TEMART” project, presented by a network of partners, including Ecor International, has officially kicked off. It aims to improve the functional and aesthetic characteristics in the fields of artistic craftsmanship, restoration of cultural heritage, furnishing (with particular reference to the lighting sector), architectural and urban decor and design.

The aim is to obtain a series of innovative technological components. In particular, there is talk of interior furnishing components made of sheet metal that can be produced without welding; energy-active products (such as boilers) consisting of porous parts made of material resistant to high temperatures (and with the function of catalysts, i.e., able to reduce pollutants or improve combustion); lamps that integrate lighting engineering with the exchange of information with the environment.

These results will be possible by enhancing and combining artistic expertise and know-how regarding the shape of the components with the technical and scientific skills shared within the network. The aim is to develop new combinations of aesthetic research with manufacturing technologies and materials.

TECHNOLOGIES AND EXPERTISE

The project, which received a loan of €2.43 million from the Veneto Region, provides for the use of:

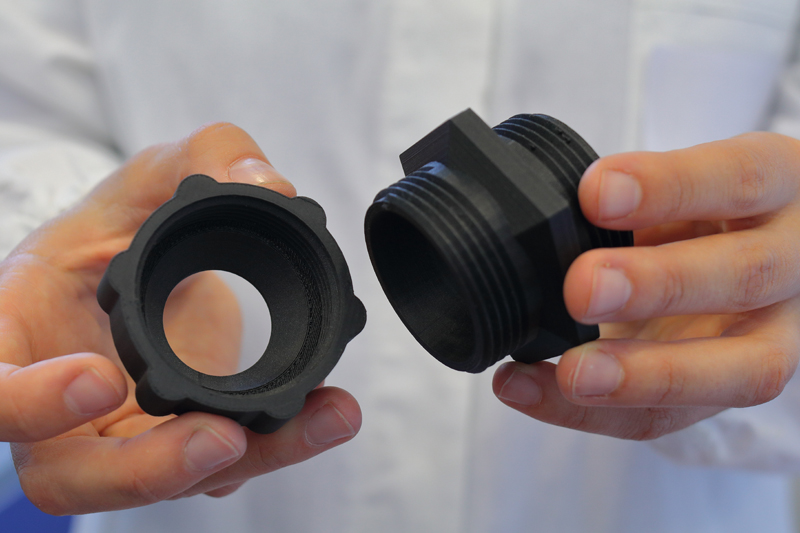

- Additive manufacturing technologies, for a wide range of materials and their combinations in the same item;

- Surface treatments and coatings of items;

- Innovative subtractive technologies (e.g., innovative machining for chip removal, micro-machining, laser machining for ablation and texturing, superfinishing)

- Innovative moulding technologies (MIM, moulding and overmoulding, dieless technologies).

Ecor International will make its expertise available in terms of process/product systems and specifically in the following areas:

- Special welding technologies;

- Additive manufacturing of metals and composite/hybrid materials;

- Surface engineering and in particular surface functionalisation by coating with technologies such as, for example, PVD, CVD, Sol-Gel;

- Metrology and reverse engineering;

- Non-destructive testing, industrial radiography;

- Special welding technologies.

THE PROJECT PARTNERS

Like the other projects in which the company participates (PoEMA, Steelwind, TresClean, NPFP), universities and some regional innovative networks (such as M3NET, Euteknos, Venetian Smart Lighting and Venetian Innovation Cluster for Cultural and Environmental Heritage) will work closely together here, in the belief that only by providing integrated knowledge and skills it is possible to achieve innovative and effective results.

Ecor International is a partner of the M3NET network, which operates in the field of specialization of smart manufacturing. It also includes the companies Delka Srl, Dff Srl, Enginsoft Spa, Metal Finish Srl, Officina Dei Materiali Sas, Prismatech Srl, Prs Srl, Pfactor Srl, and Var Connect Srl.

The universities include the Departments of Industrial Engineering and Cultural Heritage of the University of Padua, the Department of Computer Science and Biotechnology of the University of Verona, the Department of Environmental Sciences, Computer Science and Statistics and Molecular Sciences and Nanosystems of the University of Venice and the Department of Design and Manufacturing in Complex Environments of the IUAV of Venice.

The project is expected to be completed by the end of 2020.

TO KNOW

- Ablation is a process by which material is removed through the use of a highly localised heat source.

- Laser texturing is a Surface Engineering process used to improve materials surface characteristics, for example the resistance to synergistic effects of corrosion and wear, wettability, antibacterial. It consists on using a laser to create microstructures in materials surface improving load capacity, wear rate and lubrication duration and reducing friction coefficients.

- Physical Vapor Deposition, or PVD, is a high vacuum deposition method that is used to produce thin films and coatings. In particular, in this process the material is brought from a condensation phase to an evaporation phase and then again to a condensation phase of the thin film.

- Chemical Vapor Deposition, or CVD, is a high vacuum deposition method in which gaseous species react chemically to form one or more condensed phases and gaseous products.

- Sol-Gel is a method to produce ceramic materials. It takes place starting with a sol, i.e., a colloidal dispersion (a particular mixture) that constitutes a liquid system with properties close to the solid. When these solutions are modified by the action of physical and chemical processes, they produce a gel.

- Reverse engineering is a process by which an object is analysed to study its design and architecture.

- Metal Injection Molding, or MIM, is a mechanical process in which finely pulverised metal is mixed with binding material to create a raw material that is then moulded and solidified by injection moulding. In the latter process, the material is melted and injected at high pressure into a closed mould, which is then opened after solidification.

- Regional Innovative Networks are systems of companies and public and private entities, recognised by Institutional Bodies (e.g., the Veneto Region), which also operate in different sectors and are able to develop a coherent set of initiatives and projects relevant to the (regional) economy.

@EcorIntern

@EcorIntern